So it got a bit busy as I look back through my recent photos. I also finally figured out how to synchronize my Windows PC with my iCloud iPhone photos (easy but you have to look it up via Google search because you need some helper apps…). So this post has some photos from prior updates that didn’t actually make it into prior updates (or even if they did – I liked them and so what if a double posting!)

Reaching back to Old Home Day in Carlisle of 2023 – a neat winter scene of Carlisle center – which looks almost like it does today on February 2nd – grin. Also a photo of my Dad’s entry – a Blue Heron observed in the pond and printed on metal

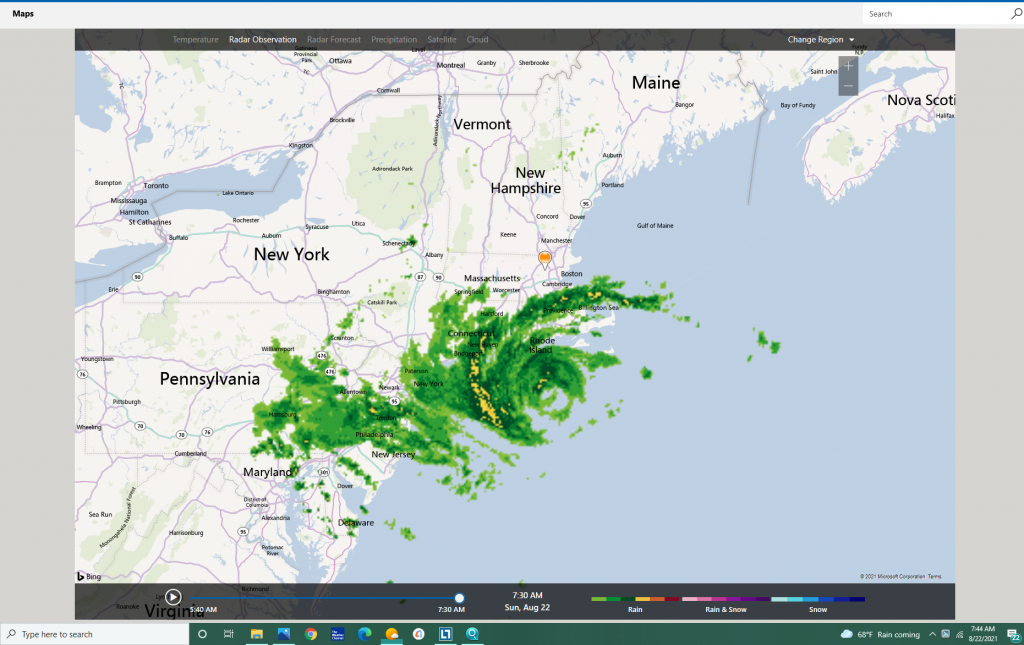

In late summer, the MBTA in Boston put in system wide slowdowns due to widespread accumulated track damage that was leading to a number of derailments. Poor management led to mass overhaul of who runs the MBTA and the new head seems pretty with it – instead of trying to fix everything via an hour or two in the middle of the night, they have put into place a measured plan over the next two years to close off sections of various lines for 2-3 weeks and then work 24 x 7 on that section and properly fix everything. Good plan and it should work – but the Red Line that I use to get into our Boston office is sooooo slowwww now. I decided to instead drive all the way in to our Everett office (where a big batch of my team works as well). So in August, I decided to actually take lunch and took a walk to the Boston Public gardens – since I may not have an easy opportunity in the future. Its really pretty neat – VERY hot day so not the best of ideas – Haha

The world famous Swan Boats – peddled by college students

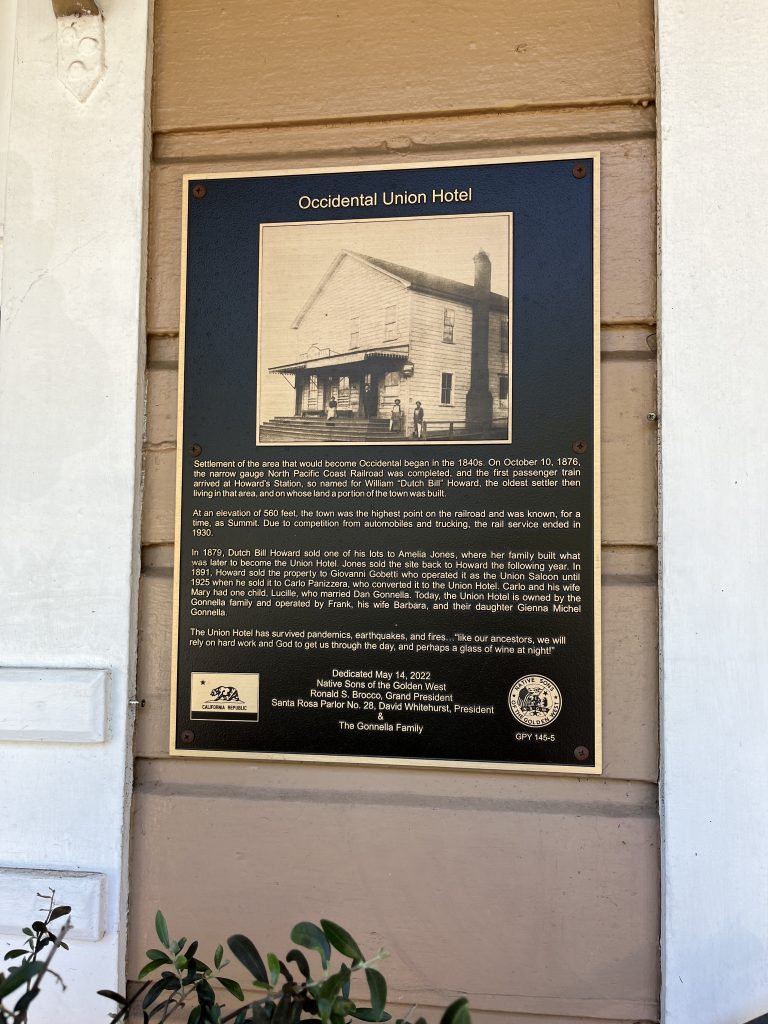

Some photos of my trip, meeting up with my old College roommates in September of 2023 – we took a day trip to Occidental – a small town in the woods near Jenner on the Sonoma coast. Neat little town, cool Redwood park near by. I especially liked the local map, painted as a mural on the side of one of the shops. Very reminiscent of Nantucket (which I am going to visit with Tom McGillvray in March 🙂 )

On my way up to the Sonoma coast, I did stop in San Francisco and took a day to walk from Downtown, to the Golden Gate bridge and back (about 8 miles). It was one of the 5 days a year that it is truly hot and windless in San Francisco – so lots of sweat and actual blisters from the sidewalk heat – something like 97 degree air temp!

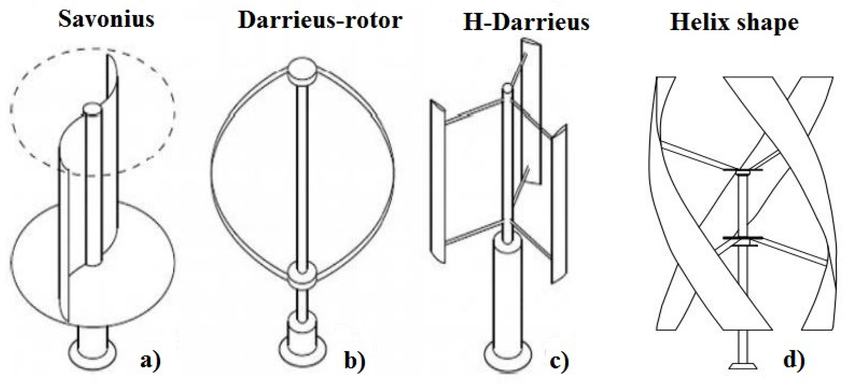

Vertical rotor windmill demonstration on the Presidio at Chrissy Field. Half of them have been disassembled, presumably for maintenance – but I attached a graphic of the various types that are normally running in the high winds common along The Slot (the area between Alcatraz and the Bridge)

In December I went to New York City to help with some planning sessions as the Bank is embarking on a journey to remake how it operates – trying to operate more like a software company in day to day function, in order to get more efficient and operate faster. Personally I think it is good plan and we are working hard at making it happen. Our CEO notes that company culture eats strategy for breakfast – so he is really focused on getting everyone lined up. A multi-year plan but it feels like we have a good start.

Anyway – I was staying near the 9/11 memorial and I took some shots at sunrise of the horse statue commemorating the Special Forces soldiers who worked in Afghanistan shortly after 9/11. Wikipedia article on this bronze statue here. In person it is really neat – hard to photography and kind of an out of the way location – but still cool.

https://en.wikipedia.org/wiki/America%27s_Response_Monument

Also in December, I managed to get the coal forge lit and working. I started pounding on some metal, hopefully what will become some sculpture for the 2024 Old Home Day art show. I am using some old scrap wrought iron – a 2 inch square wagon axle. The coat we have is not very good and man is it a lot of work to get a hot fire going. 90 minutes of sweating to make a hot enough fire doesn’t leave a lot of energy for heavy pounding – so I am thinking I will need to refurbish the gas stove or do something, otherwise I won’t get anything done at this rate – lol

good fun though!

Rolling into January of 2024 – I got inspired from talking with Eric Bonzell and Eric Moeller about camping and I have been thinking for a while that the two Subaru station wagons we have in Carlisle sometimes are too small – so I decided to do something about it. Specifically, I decided to pull a trigger on an idea I had since the middle 1980’s when we spent a lot of time offroading in Anza Borrego and other desert locations east of UC San Diego. Specifically getting a Chevy Suburban and set it up as a work truck and camper/overlander rig. The idea being that the Suburban is fully enclosed, with the 2nd and 3rd row of seats out, has the same cargo space as a long bed pickup AND there is a second set of doors so you can get to things instead of crawling around. I did some internet digging and stumbled onto a small family business in Twin Falls, ID called Suboverland. They find older Suburbans, refurbish them and set them up for camping. I got in touch with them and had them source locally a 1999 GMC Suburban in great shape, refresh it (driveline maintenance, shocks, spark plugs etc…). They also put on a 12,000 pound winch, took out the 2nd and 3rd row of seats, put in a Pioneer media system with a backup camera, a 2,000 watt/hour battery system and a Dometic electric refrigerator. A 1 inch suspension lift, new All Terrain tires and a new limited slip differential in the rear. All up it was about $18,000. I picked it up the second week of January in Idaho and drove it to Massachusetts, dodging two really major blizzards in the Plains and got to visit with my Sister in Law Tenley and her husband Dan (and finally see her house in Galesburg IL – grin).

I started calling the Albino Caterpillar since it just kind of burbles its way along on the highway – super soft and comfortable. That is perfect, because the idea is that 99% of the time it will be a hobby work truck and occasional overlanding camping rig where I zoom cross country to meet up with the old roomates and camp around Yellowstone etc…

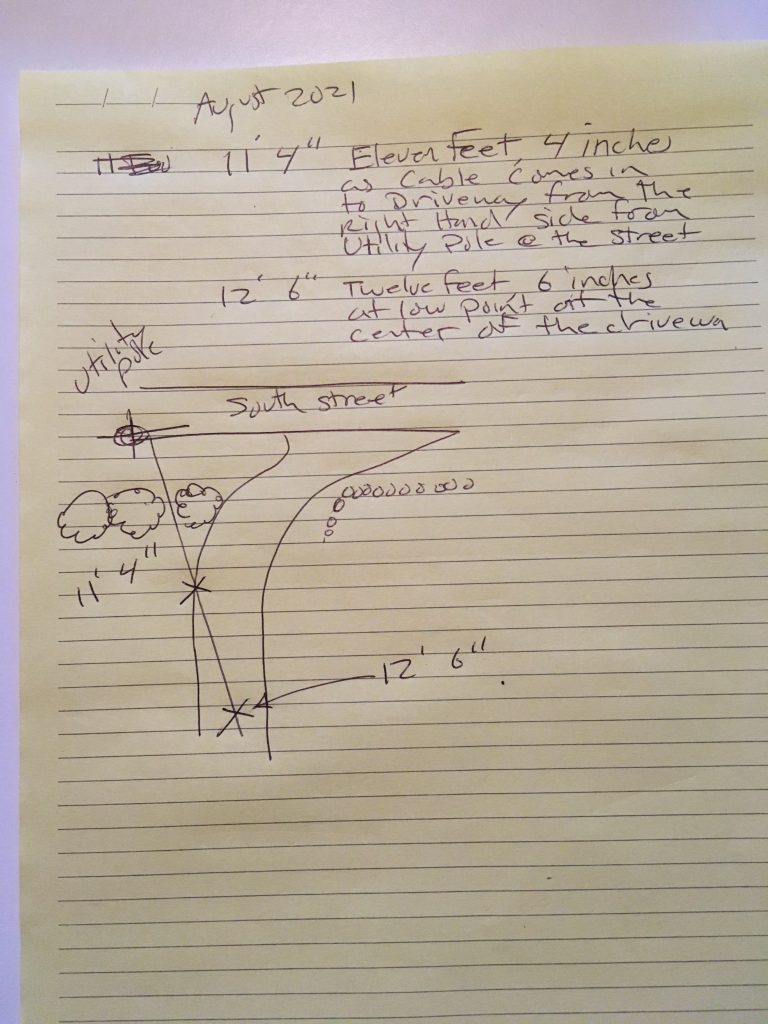

Since getting it home safe and sound, my Dad and I have already hauled some Black Walnut logs – haha. Next things on the docket are we are getting it setup to haul around his 3 wheel recumbent bicycle that just doesn’t quite fit in their Subaru Forrester. We got a light duty ATV electric winch from Warn (over kill a 1/2 done weight rating – but it was the smallest that came in a good form factor and had a remote operation controller). Plan is a plywood ramp and my Dad can winch the bike in and out on his own – so he can go riding midweek while I am at work (and he can keep the ‘Burb running and active). The winch has arrived and we took measurements last night – next up is some wood and do some engineering. Good fun and I will save that for the next update.

Hope anyone who is reading this is having a good winter!

Here is a Youtube video made by Suboverland (I HIGHLY recommend them) of my truck.